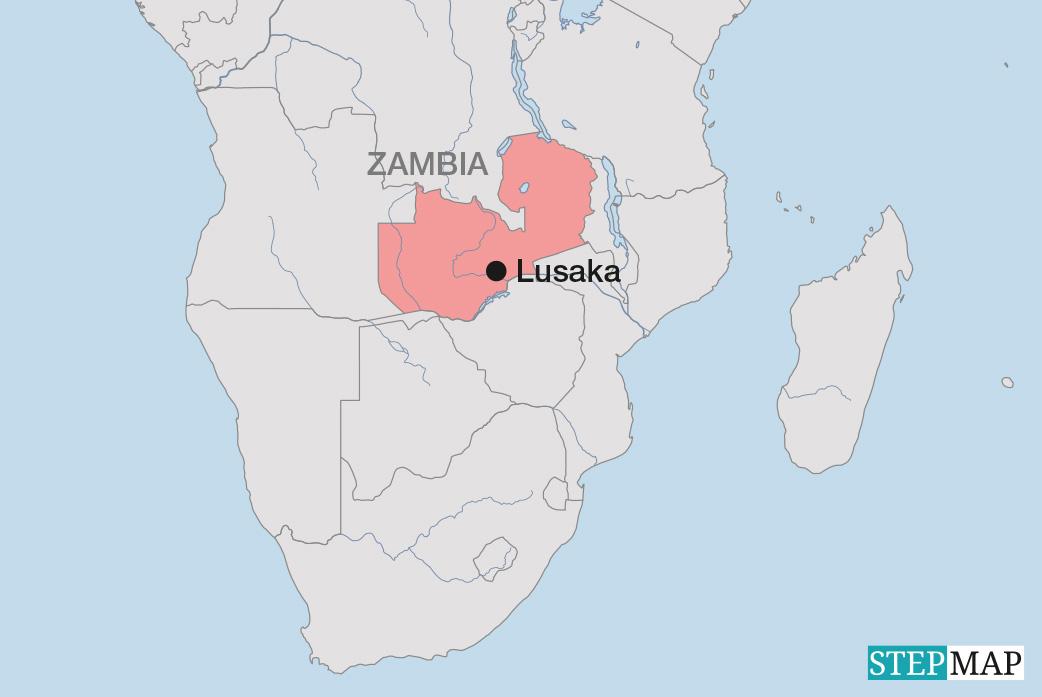

Ivanhoe Mines Delivers First Anodes at Kamoa-Kakula, Marking a New Era for African Copper Smelting

Image: Kamoa-Kakula

Ivanhoe Mines has achieved a major operational milestone with the first production of copper anodes at its Kamoa-Kakula Copper Complex, following the successful commissioning of Africa’s largest copper smelter, rated at 500,000 tonnes of copper per annum.

The first anodes were cast on 29 December 2025, just five weeks after heat-up commenced and one week after the first concentrate feed—an accelerated timeline that underscores the scale, engineering discipline, and execution capability behind the US$1.1-billion project.

Africa’s Largest Copper Smelter Comes Online

The direct-to-blister smelter has been designed to produce 99.7%-pure copper anodes, allowing Kamoa-Kakula to move decisively up the value chain by converting concentrates into refined products on site rather than exporting unbeneficiated material.

As ramp-up progresses through 2026, the smelter is expected to reach steady-state output of 500,000 tonnes per year, positioning Kamoa-Kakula as a strategic supplier of high-purity copper to global markets at a time of structurally strong demand driven by electrification and energy-transition metals.

2026 Sales to Outpace Production on Inventory Destocking

Ivanhoe expects 2026 copper sales to exceed production by approximately 20,000 tonnes, as previously stockpiled concentrate is smelted and sold as anodes. At the start of smelter operations, on-site inventories held roughly 37,000 tonnes of contained copper in concentrate. As ramp-up continues, unsold inventory is expected to decline to around 17,000 tonnes by year-end.

This timing is commercially significant. Management intends to capitalise on near-record copper prices, converting inventory into higher-value anodes during the first half of 2026, improving cash flow and margins.

Smelter Ramp-Up and Processing Strategy

Total Kamoa-Kakula copper production for 2026 is forecast at 380,000–420,000 tonnes, with a midpoint of 400,000 tonnes, equivalent to roughly 80% of smelter capacity. Concentrate from Phase 1, 2, and 3 concentrators will be prioritised for on-site smelting, while any excess material will be toll-treated at the nearby Lualaba Copper Smelter.

Hot commissioning of the furnace, boiler systems, steam circuits, acid plant, and concentrate dryer was completed on schedule. The furnace sustained its 1,250°C operating temperature for five consecutive days prior to the first feed—confirming design and thermal stability.

Power Security and Renewable Integration

Operational resilience has been further strengthened through the completion of a 60-megawatt uninterruptible power supply (UPS) system, providing up to two hours of instantaneous back-up power to protect the smelter from grid volatility in the DRC.

In parallel, construction is advancing on a 60-MW on-site solar photovoltaic facility with battery storage, expected to be one of the largest mining-linked solar installations in Sub-Saharan Africa. Scheduled for commissioning in Q2 2026, the project will deliver round-the-clock power alongside approximately 180 MW of diesel-powered backup generation, materially reducing energy risk and emissions intensity.

Margin Expansion Through Beneficiation and Acid Sales

The move to on-site smelting is expected to significantly expand operating margins. Logistics costs are forecast to halve, as the copper content per exported truckload increases from roughly 45% in concentrate to 99.7%-pure anodes.

Additional upside comes from by-product sulphuric acid. The smelter is designed to produce up to 700,000 tonnes per annum of high-strength acid at steady state. Local demand across the Central African Copperbelt is acute, particularly following Zambia’s acid export ban in September 2025, which has pushed spot prices in Kolwezi as high as US$700 per tonne. Kamoa-Kakula has already completed its first acid sale, with deliveries commencing shortly.

Industry-Leading Safety Performance

Construction of the smelter was completed with an exceptional health and safety record. Over 18 million hours worked, only one lost-time injury (LTI) was recorded, equating to a lost-time injury frequency rate (LTIFR) of approximately 0.054 per million hours—well below global industry benchmarks.

This follows the successful delivery of the Phase 3 concentrator in mid-2024, which was completed without a single LTI.

Kakula Mine Dewatering Advances Ahead of Schedule

Underground operations also recorded major progress. Stage Two dewatering at the Kakula Mine has been completed, with high-capacity submersible pumps now running dry. Water levels have fallen a further 19 metres since late November, with the remaining Stage Two pumps expected to cease operation in January 2026.

Stage Three dewatering—focused on rehabilitating underground horizontal pump stations for steady-state operations—is scheduled to continue into Q2 2026 and is not on the project’s critical path.

With the western side of Kakula fully dewatered, mining has resumed in higher-grade zones. Head grades are expected to rise from 3.5% copper in January to approximately 4.0% by the end of Q1 2026. Selective mining on the eastern side also commenced ahead of schedule in late December.

Strategic Significance

For MiningFocus Africa, the commissioning of the Kamoa-Kakula smelter represents more than a project milestone—it is a structural shift in Africa’s copper industry. By combining scale, beneficiation, renewable power integration, and downstream value capture, Ivanhoe Mines is setting a new benchmark for how world-class copper assets can be developed on the continent.

Share this content: