Theta Gold Mines makes strong progress

Theta Gold Mines makes strong progress on DFS for TGME underground gold project in South Africa

The overall Definitive Feasibility Study (DFS) is progressing well and is currently in the QA/QC phase with an expected completion before the end of this quarter.

Theta Gold Mines Ltd – Theta Gold Mines makes strong progress towards DFS of TGME underground project in South Africa

The company has completed the front-end engineering design (FEED) of the TGME gold plant, forming an important input for the finalisation of the DFS.

Notably, the overall DFS is currently in the QA/QC phase with completion expected before the end of this quarter.

“DFS progressing well”

Theta chairman Bill Guy said: “DFS is progressing well, and the drafts are currently under internal review.

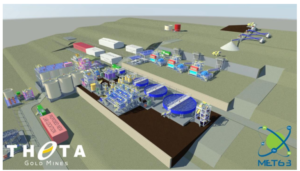

“The process plant has been designed by MET63, an experienced consulting team from South Africa.

“The plant is designed to cater for different ore streams as different TGME gold mines will be brought on stream.

“More than 80% of the plant components and raw materials are expected to be sourced locally from South African suppliers.

“South Africa has numerous mine equipment manufacturers and suppliers.

“The modular design means easy expansion for future growth and reduces construction time.”

Key features

- Theta has appointed MET63, a company that specialises in the design and construction of advanced modular processing plants to undertake and complete the plant design based on a thorough metallurgical test-work program and with multi-tier internal and independent oversight.

- Key process plant features:

- The new gold process plant is designed to have a milling capacity of 540,000 tonnes per annum. The plant design consists of two individual processing streams, capable of processing free-milling and sulphide ore separately.

- The new plant is designed to fit into the current plant footprint which forms part of the Mining Right MR83, therefore no additional environmental permitting will be required.

- The new processing plant components include three-stage crushing, milling, reagent, flotation, CIL, elution and gold room sections.

- The gold plant will produce dore gold bars.

- Engineering and costing have been completed to the required level of accuracy for the DFS.

- The completed design includes water and power reticulation with the scope to increase the capacity with modular units for future plant expansions, consistent with the company’s strategy to reach its gold production target of 160,000 ounces per annum within five years

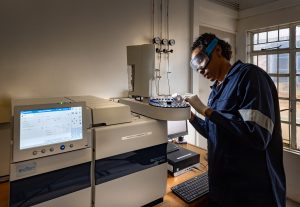

- The latest proven available automation technologies are incorporated in the gold processing plant design to reduce labour requirements and enhance productivity levels.

- The tailings disposal will be onto the existing tailings storage facility located some 150 metres from the plant.

- Some existing plant infrastructures were incorporated into the new gold processing plant.

New TGME plant layout.

As site operations, the permitting process and DFS workings continue, TGM also advises that CEO Mr Mitford Mundell is no longer employed with the company.

Share this content: